A: Extractor set is easier to control the flow & performance. Our extractor set comprises of 4 extractor stages, with our line process expertise, we can maximize yield and at the same time easy to control. The unit operates with 4 fiber pump, 4 starch pump and our built-in process control unit which simplifying the control for production staffs.

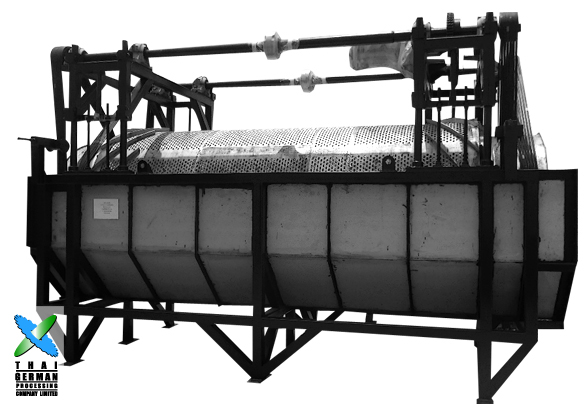

A: Paddle type root cleaner has many paddles and fasteners, the numbers of parts create more often downtime and time consuming for maintenance. The squirrel type root washer is easier for maintenance because the most often part for maintenance is only belt.

The broken root from squirrel type is fewer because the root is not being pushed by the paddle and broken, therefore the loss of starch from fragmented roots also lower.

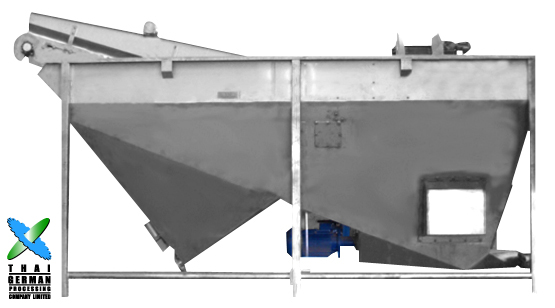

A: The efficient destoner unit helps to prevent stone, pebble, and metals chips get into root chopper & rasper. Especially rasper, which having saw blade to mill the tapioca roots. Once stone get into the rasper, the rasper saw tooth will be broken, therefore no saw tooth to mill the root anymore, the yield of tapioca starch will be lower.

Good performance destoner

Low performance destoner

A: Apart from precision of weight scaling which is compulsory for the standard bagging machine, the machine itself should be good in preventing leakage of starch from the hopper shoot or other joint areas. This would prevent the loss of starch and also create a clean working environment for the staffs.

A: Nowadays, the waste water from tapioca starch product isn’t a problem anymore. We can effectively comply the regulation from government about waste water.

The waste water and tapioca waste is a good material for making biogas. The biogas will be used either heat source for heat exchanger, or used as fuel for electric generator. You can use the electric either for your own consumption or sell to the Electric Authorities.

Thai German Processing not only experienced in starch production but also the biogas system. For waste water after biogas process, we can treat either SBR or Setting Pond type system, Thai German Processing have extensive experience to manage it.